Complex Life Science Project with a Tight Timeline Proves Successful

A plant-wide project that touches 90% of your manufacturing and 90% of your packaging systems would be a daunting undertaking for any manufacturer. If you are a heavily regulated pharmaceutical life sciences company, those stakes are even higher. Technically competent resources, project planning, coordination and communication are all critical to success.

A plant-wide project that touches 90% of your manufacturing and 90% of your packaging systems would be a daunting undertaking for any manufacturer. If you are a heavily regulated pharmaceutical life sciences company, those stakes are even higher. Technically competent resources, project planning, coordination and communication are all critical to success.

Huffman Engineering had just that sort of project on their hands when a local large pharmaceutical manufacturing and packaging plant underwent a change in ownership. The project involved migrating off of the prior owner’s servers and network infrastructure onto the new company’s servers and network infrastructure, as well as computer upgrades, software upgrades and transfer in ownership of software.

It takes a committed community! The customer approached this as a partnership from the start. It was a joint effort between the customer, Rockwell, Rockwell’s local distributor – the Lincoln branch of Consolidated Electrical Distributors (CED), and Huffman Engineering.

Huffman Engineering’s team had the advantage of extensive knowledge of this facility from working with several previous owners since 1994. However, successful completion of this huge undertaking required much more than a working knowledge of the facility. Huffman Engineering’s partners relied on Huffman Engineering’s extensive experience in meeting regulatory requirements for 21 CFR Part 11 Federal Drug Administration (FDA) regulations, coupled with their expertise in IT networking and Rockwell Automation integration.

“Huffman Engineering took a complex project with a tight schedule and performed within budget and beyond expectations,” said Wes Lehman, manager, CED Lincoln. “They took ownership of their responsibilities, reviewed others’ responsibilities, and communicated well with all parties to keep the project moving regardless of issues that had arisen. I am thankful that Huffman Engineering was on our team.”

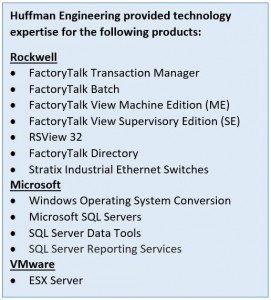

CED Lincoln provided hardware and software required for the project. Rockwell did most of the upfront development work for the project. Huffman Engineering’s work began four months prior to installation. As a Rockwell Automation Control and Process Solution Provider, Huffman Engineering provided technical review and software development assistance to the Rockwell team to ensure regulatory 21CFR11 compliance. Huffman Engineering was responsible for all compliance qualification documentation including Installation Qualification (IQ), Operational Qualification (OQ) and Performance Qualification (PQ). In addition, Huffman Engineering’s team led project management and deployment onsite.

CED Lincoln provided hardware and software required for the project. Rockwell did most of the upfront development work for the project. Huffman Engineering’s work began four months prior to installation. As a Rockwell Automation Control and Process Solution Provider, Huffman Engineering provided technical review and software development assistance to the Rockwell team to ensure regulatory 21CFR11 compliance. Huffman Engineering was responsible for all compliance qualification documentation including Installation Qualification (IQ), Operational Qualification (OQ) and Performance Qualification (PQ). In addition, Huffman Engineering’s team led project management and deployment onsite.

As part of the network infrastructure upgrade, Huffman Engineering built 9 virtual servers and used Microsoft SQL Server Reporting Services to create reports that run on a report server. In addition, Huffman Engineering upgraded the computer operating systems from Windows XP, which is no longer supported by Microsoft, to Windows 7.

Huffman Engineering’s knowledge of server setup, virtualized environments, network infrastructure and communications was key to testing and optimizing software before installation. Of the 9 new servers, Huffman Engineering used VMware ESX, an enterprise-level virtualization tool, to run numerous virtual machines used to simulate and test performance prior to deployment.

Huffman Engineering’s knowledge of server setup, virtualized environments, network infrastructure and communications was key to testing and optimizing software before installation. Of the 9 new servers, Huffman Engineering used VMware ESX, an enterprise-level virtualization tool, to run numerous virtual machines used to simulate and test performance prior to deployment.

As they often are, time constraints were critical for this customer. The customer was also upgrading SAP so knew they were going to have a one-week outage for their SAP upgrade. Therefore, the target was to complete onsite installation and validation in conjunction with that one-week window of downtime.

As the team responsible for deployment, Huffman Engineering functioned as ‘the closer.’ This is where Huffman Engineering’s integrated knowledge became essential. The team had to understand the entire breadth of the system to bring everything together and clear any problems.

“Our best asset is our people, and that was very evident in the project. Our dedicated team of eight put in three 70+ hour weeks onsite – prior to the scheduled install,” said Howard Huffman, CEO, Huffman Engineering. “Many worked nineteen days in a row. They resolved inevitable omissions and picked up the loose pieces in very short order to get everything successfully installed and validated. We are very proud of our team’s ability to complete this project ahead of schedule and exceed our customer’s expectations.”

Actually, one of Huffman Engineering’s team members turned 21 during the startup – and was back onsite before 8am the next day. Now that’s dedication! This was a very complex project with a lot of moving parts that required teamwork and an in-depth knowledge of regulatory compliance and the various technologies used to be able to pull it off successfully. A celebration is being planned to congratulate Huffman Engineering’s Life Sciences Team for a job well done!